На первой странице > Контроль качества - 品质控制

Производство

品质控制

我们的目标是产成品零缺陷

Our target : 0% defects

1. Receiving inspection

• All materials must be with certificates, and must pass our receiving inspection before launching into production.

All materials will be tagged and classified, so the original source could be traced at any time during production process.

• 1. 进料检验

所有的原材料都必须有供应商的证明,且在投

入生产之前必须通过进料检验。所有的原材料都将标记归

类,这样可以对原来的来源进行追踪。

Intermediate inspection

• 2. 中期检验

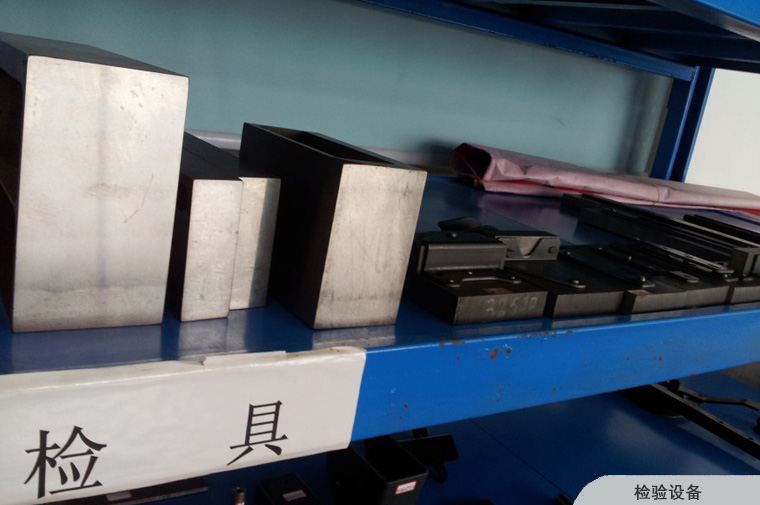

• Every step of producing process will be monitored by intermediate inspection.

The first product in every step shall be tested. Only completing the test and confirmed by QC, it could go into mass production.

Every operator will implement constant tests during production process, including size-measuring, observing the appearance and exterior characteristics.

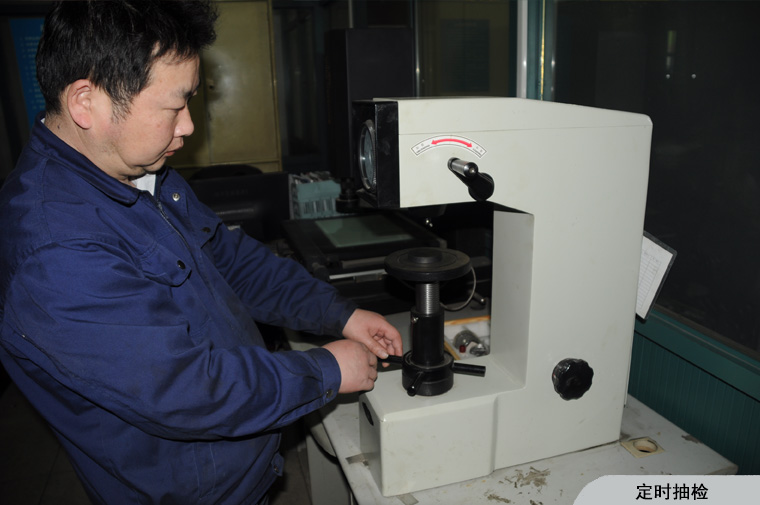

QC will inspect the samples from every machine and sampling in timely manner.

• 生产的每个阶段都要由中期检验进行监控。

在生产的每个阶段都要对第一件产品进行检验。只有在检验完成并由质量控制经理确认通过后才能开始批量产品的生产。

每一台机器的操作员在生产过程中会进行持续的检验。如用量具测尺寸、观察产品的外观和表面特性。

检验员会定时地检查从每台机器做出的产品样品,定时取样。

• Final inspection

• 3. 末期检验

• Products can go into warehouses only after checking by the final QC.

• 在最后一关,只有检验员通过后,产品方能入库。